A circuit breaker is a safety device that protects electrical circuits from overcurrent or short circuits by interrupting the current flow․ It operates manually or automatically to shield equipment, preventing damage and fire hazards, ensuring reliable power distribution․

Air Circuit Breakers

Air circuit breakers (ACBs) use atmospheric pressure air as an arc-quenching medium, providing reliable fault interruption in medium and low voltage systems․ They are widely used in indoor switchgear․

2․1 Fixed Type

The fixed-type air circuit breaker is a stationary installation, typically mounted on vertical panels or integrated into indoor switchgear․ This design is preferred for its simplicity and reliability in low and medium voltage applications․ Unlike draw-out types, fixed breakers cannot be removed for maintenance, requiring on-site servicing․ They are ideal for systems where space is limited and vibration or movement is minimal․ Fixed ACBs are known for their robust construction, making them suitable for industrial and commercial environments․ Their arc-quenching capability ensures efficient fault interruption, and they are often used in applications where continuous operation is critical․ This type is cost-effective and requires less complex installation compared to draw-out models․

2․2 Draw-Out Type

The draw-out type air circuit breaker is designed for flexibility and ease of maintenance․ It features a modular design where the breaker can be withdrawn from its enclosure while the system remains energized, allowing for safer servicing and testing․ This type is commonly used in industrial and commercial switchgear due to its convenience and reliability․ The draw-out mechanism is typically mounted on a cradle, enabling easy removal and reinsertion without dismantling the entire system․ This design minimizes downtime and enhances operational efficiency․ Draw-out breakers are preferred in applications where frequent maintenance or upgrades are anticipated, ensuring uninterrupted power distribution in critical systems․ Their robust construction and arc-quenching capabilities make them suitable for demanding environments․

Molded Case Circuit Breakers (MCCB)

Molded Case Circuit Breakers (MCCBs) are widely used for protecting electrical circuits in industrial, commercial, and residential applications․ They combine a thermal and magnetic tripping mechanism to interrupt overcurrents, ensuring reliable protection․ MCCBs have a higher current-carrying capacity compared to miniature circuit breakers, ranging from 3 A to over 4,000 A․ Their compact design and durability make them suitable for various environments․ These breakers are available in fixed and draw-out versions, offering flexibility for different installations․ MCCBs are known for their adjustable settings, allowing customization to specific circuit requirements․ They are also designed for easy installation and maintenance, making them a popular choice for power distribution systems․ Their robust construction and advanced features ensure optimal performance and safety in demanding electrical networks․

Miniature Circuit Breakers (MCB)

Miniature Circuit Breakers (MCBs) are compact electrical devices designed to protect low-voltage circuits from overcurrent and short-circuit conditions․ They are widely used in residential and small commercial applications due to their small size and cost-effectiveness․ MCBs operate using a thermal-magnetic mechanism, where excessive current triggers the tripping mechanism to interrupt the circuit․ These breakers are rated for currents up to 100 A and are available in various configurations, including single-, double-, and triple-pole designs․ Their compact design and easy installation make them ideal for use in domestic and light industrial settings․ MCBs are also known for their reliability and ability to provide precise overcurrent protection, ensuring safety and minimizing downtime in electrical systems․

Thermal-Magnetic Circuit Breakers

Thermal-Magnetic Circuit Breakers combine two protection mechanisms: thermal and magnetic․ The thermal component detects overloads by sensing excessive heat caused by prolonged overcurrent, while the magnetic component quickly responds to short circuits by tripping the breaker․ These breakers are widely used in low-voltage applications, such as residential and commercial settings, due to their reliability and simplicity․ They are available in various configurations, including single-, double-, and triple-pole designs, and are known for their compact size and cost-effectiveness․ Thermal-magnetic breakers provide excellent protection against both gradual overloads and sudden fault currents, making them a versatile choice for ensuring electrical safety in diverse installations․

High Voltage Circuit Breakers

High-voltage circuit breakers are essential for protecting high-voltage electrical systems from faults, ensuring reliable power distribution․ They are designed to handle large current capacities and are widely used in transmission and distribution systems․ These breakers utilize advanced arc-quenching mechanisms to interrupt faults swiftly and maintain system stability․

6․1 SF6 Circuit Breakers

SF6 circuit breakers utilize sulfur hexafluoride gas as an insulating and arc-quenching medium․ Known for their high efficiency, these breakers excel in interrupting high-voltage faults․ They are widely used in power systems up to 765 kV․ Types include single-pressure puffer and multi-pressure designs․ SF6 breakers are valued for their reliability, compact size, and low maintenance․ However, their use is declining due to SF6’s high global warming potential․ Modern alternatives are being developed to replace these breakers while maintaining their performance․

6․2 Oil Circuit Breakers

Oil circuit breakers are a traditional type of high-voltage circuit breaker that uses oil as both an insulating and arc-quenching medium․ The oil provides effective arc extinction by cooling the arc and preventing its re-ignition․ These breakers were widely used in transmission and distribution systems due to their reliability and simplicity․ Over time, they have been largely phased out in favor of more modern technologies like SF6 and vacuum circuit breakers․ Despite their decline, oil circuit breakers remain significant in historical contexts, showcasing early advancements in electrical engineering․ Their operation involves immersing the contacts in oil, which helps in interrupting high fault currents safely․ However, concerns over maintenance and environmental impact have reduced their popularity in contemporary systems․

Low Voltage Circuit Breakers

Low voltage circuit breakers are essential components in electrical systems, primarily used in residential, commercial, and light industrial applications․ They operate at voltages up to 1,000 volts AC and are designed to protect circuits from overcurrent and short circuits․ These breakers are available in various types, including miniature circuit breakers (MCBs) and molded case circuit breakers (MCCBs)․ MCBs are suitable for lower current ratings, while MCCBs can handle higher currents within the low voltage range․ They operate using thermal or magnetic mechanisms to detect and interrupt faulty currents, ensuring safe and reliable power distribution․ Low voltage breakers are widely used in protecting household appliances, lighting systems, and small industrial equipment, making them indispensable for maintaining electrical safety and efficiency in everyday applications․

Vacuum Circuit Breakers

Vacuum circuit breakers are highly efficient and reliable devices used for medium voltage applications․ They utilize a vacuum as the arc-quenching medium, providing excellent insulation and arc extinction capabilities․ When a fault occurs, the contacts separate within a sealed vacuum chamber, extinguishing the arc quickly and effectively․ These breakers are widely used in industries, substations, and power distribution systems due to their low maintenance requirements and long service life․ The vacuum environment ensures minimal noise and no gas emissions, making them environmentally friendly․ They are also known for their high reliability and resistance to external factors like humidity and dust․ Vacuum circuit breakers are ideal for applications requiring frequent switching operations and are considered a modern alternative to older technologies like oil and SF6-based breakers․

Arc Fault Circuit Interrupters (AFCI)

Arc Fault Circuit Interrupters (AFCIs) are advanced electrical safety devices designed to detect and interrupt dangerous arcing faults, which can lead to electrical fires․ Unlike traditional circuit breakers, AFCIs monitor the electrical current for irregular patterns that indicate arcing, such as sparks or unintended electrical discharges․ These devices are critical in modern electrical systems, particularly in residential settings, where arcing faults often occur due to damaged or aging wiring․ AFCIs are mandated by many electrical codes for areas like bedrooms and living rooms to enhance fire safety․ They work by interrupting the circuit when an arc is detected, preventing overheating and potential ignition of nearby materials․ AFCIs are essential for protecting lives and property from fire hazards caused by electrical malfunctions․

DC Circuit Breakers

DC circuit breakers are specialized electrical devices designed to interrupt direct current (DC) in electrical systems․ Unlike AC circuit breakers, DC breakers must handle the unique challenges of direct current, which does not naturally zero-cross, making arc extinction more complex․ These breakers are crucial in applications like high-voltage DC (HVDC) transmission systems, renewable energy installations, and electric vehicle charging infrastructure․ DC circuit breakers often utilize advanced technologies such as vacuum chambers or SF6 gas to quench arcs effectively․ They are designed to operate within specific voltage and current ratings, ensuring reliable protection against faults such as short circuits or overloads․ As DC power systems grow in importance, DC circuit breakers play a vital role in maintaining safety and efficiency in modern electrical networks․

Hybrid Circuit Breakers

Hybrid circuit breakers combine electronic and mechanical components to achieve high performance and reliability․ These breakers integrate advanced semiconductor devices with traditional mechanical switching mechanisms, offering precise control over current interruption․ They are designed to handle both AC and DC systems, making them versatile for various applications․ Hybrid breakers are known for their fast switching speeds, low power consumption, and ability to handle high fault currents․ They are widely used in industrial power systems, renewable energy installations, and high-voltage direct current (HVDC) transmission systems․ Their compact design and reduced maintenance requirements make them a preferred choice for modern electrical infrastructure․ Hybrid circuit breakers represent a significant advancement in circuit protection technology, blending the best features of electronic and mechanical systems to ensure efficient and safe operation․

Construction Types

Circuit breakers are built in two main constructions: fixed type, mounted directly on panels, and draw-out type, designed for easy removal without dismantling the switchgear assembly․

12․1 Fixed Type

The fixed type circuit breaker is permanently mounted on a panel or switchgear assembly, making it a compact and space-saving solution․ Unlike draw-out types, these breakers cannot be removed without dismantling the surrounding equipment․ They are commonly used in low-voltage applications and are ideal for systems where maintenance is less frequent․ Fixed-type breakers are cost-effective and simple to install, offering reliable protection for residential and small commercial electrical systems․ Their design ensures that they are directly integrated into the power distribution unit, providing a straightforward and efficient means of circuit protection․ This construction type is preferred in applications where mobility and frequent servicing are not required, making it a practical choice for fixed electrical installations․ Fixed-type circuit breakers are widely used due to their durability and ease of operation;

12․2 Draw-Out Type

The draw-out type circuit breaker is designed to be easily removable and reusable, offering enhanced flexibility and maintenance convenience․ These breakers are mounted on rails or slides, allowing them to be withdrawn from the switchgear without disconnecting wires․ This feature simplifies maintenance, testing, and replacement, reducing downtime in industrial and commercial applications․ Draw-out breakers are commonly used in medium- and high-voltage systems, where regular servicing is critical․ They often include a cradle or carriage system, enabling smooth extraction and reinstallation․ This type is particularly advantageous in large electrical systems, where ease of access and quick servicing are essential․ Draw-out circuit breakers are available in both fixed and motorized configurations, catering to diverse operational needs and ensuring reliable power distribution and protection․

Historical Significance

The development of circuit breakers has played a pivotal role in the evolution of electrical power systems․ Early versions, such as oil circuit breakers, emerged in the late 19th century, providing a foundational method for interrupting high-voltage circuits․ These early designs laid the groundwork for modern technologies like air blast and SF6 circuit breakers, which became essential for large-scale electrical distribution․ The historical significance of circuit breakers lies in their ability to enable the expansion of electrical networks while ensuring safety and reliability․ Over time, advancements in materials and mechanisms have led to more efficient and compact designs, such as vacuum and thermal-magnetic circuit breakers․ This progression highlights the critical role of circuit breakers in shaping the modern electrical infrastructure, ensuring protection, and facilitating the growth of industrial and residential power systems․

Working Principles

Circuit breakers operate by detecting overcurrent or short circuits, triggering a response to interrupt the electrical flow․ Magnetic operation uses a solenoid to trip the breaker, while thermal operation relies on a bimetallic strip bending under excessive current to open the circuit․

14․1 Magnetic Operation

Magnetic operation in circuit breakers involves a solenoid that detects excessive current, such as in short circuits․ When the current exceeds a set threshold, the solenoid generates a magnetic field, which moves a metal lever to open the circuit․ This mechanism is faster than thermal operation, providing immediate interruption for severe faults․ The magnetic trip unit is calibrated to respond to specific current levels, ensuring quick disconnection to protect the system․ This method is often combined with thermal operation in hybrid breakers for comprehensive protection․ Magnetic operation is highly reliable and widely used in various applications due to its rapid response capability and effectiveness in safeguarding electrical systems from damaging faults․

14․2 Thermal Operation

Thermal operation in circuit breakers relies on heat generated by excessive current․ A bimetallic strip is used, which bends when exposed to increased temperatures caused by overcurrent conditions․ This bending action triggers the circuit breaker to open, interrupting the flow of electricity․ Thermal operation is primarily designed to protect against overloads rather than short circuits․ It is slower than magnetic operation but effective for gradual overcurrent scenarios․ In many cases, thermal and magnetic mechanisms are combined in hybrid devices to provide comprehensive protection․ This dual approach ensures that both sudden faults and prolonged overloads are safely managed; Thermal operation remains a reliable method for safeguarding electrical systems from damage caused by excessive heat buildup over time․

14․3 Hybrid Operation

Hybrid operation in circuit breakers combines thermal and magnetic mechanisms to provide enhanced protection․ This dual-system approach ensures rapid response to both gradual overloads and sudden short circuits․ The thermal element detects prolonged overcurrent, while the magnetic element reacts instantly to high fault currents․ Together, they offer comprehensive protection for electrical systems․ Hybrid operation optimizes performance by leveraging the strengths of both methods, ensuring faster tripping times and improved reliability․ This integrated design is widely used in modern circuit breakers to address a broad range of fault conditions effectively․ By combining thermal and magnetic technologies, hybrid operation balances sensitivity and speed, making it ideal for safeguarding complex electrical networks from various types of faults and overcurrent scenarios․

Applications

Circuit breakers are essential in various applications, including residential, industrial, and commercial settings․ They protect electrical systems from overcurrent, ensuring safety and reliable power distribution across different sectors․

15․1 Residential

Circuit breakers play a vital role in residential electrical systems, ensuring safety and reliability․ They protect homes from overcurrent and short circuits, preventing damage to appliances and reducing fire risks․ Miniature circuit breakers (MCBs) are commonly used in household applications due to their compact size and sensitivity to small current fluctuations․ These devices are designed to interrupt the power supply instantly in case of an overload, safeguarding both the electrical system and connected devices․ Additionally, molded case circuit breakers (MCCBs) are employed in larger residential settings where higher current capacities are required․ By providing efficient protection, circuit breakers ensure uninterrupted power supply and maintain the integrity of residential electrical networks․

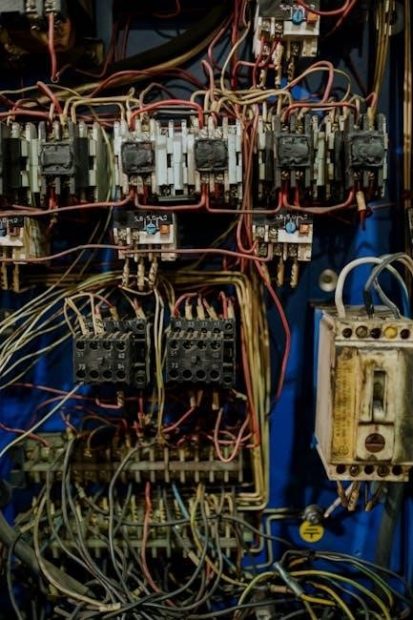

15․2 Industrial

In industrial settings, circuit breakers are essential for safeguarding complex electrical systems and machinery․ They protect against overloads, short circuits, and voltage fluctuations, ensuring uninterrupted production and minimizing downtime․ Industrial circuit breakers, such as air circuit breakers (ACBs), vacuum circuit breakers (VCBs), and SF6 circuit breakers, are designed to handle high currents and operate in harsh environments․ These devices are often integrated into power distribution units (PDUs) and switchgear systems to provide reliable protection for motors, generators, and other heavy-duty equipment․ Their robust construction and advanced features, such as high fault current interruption capacity, make them critical for maintaining industrial safety and efficiency․ Regular maintenance of these breakers is crucial to ensure optimal performance and prevent operational failures․

15․3 Commercial

Circuit breakers play a vital role in commercial electrical systems, ensuring safe and reliable power distribution in offices, retail spaces, and industrial facilities․ They protect against overloads, short circuits, and voltage spikes, which are common in high-demand environments․ Commercial-grade circuit breakers, such as molded case circuit breakers (MCCBs) and miniature circuit breakers (MCBs), are designed to handle medium to high current ratings, making them suitable for powering heavy machinery, lighting systems, and IT infrastructure․ These devices often feature advanced technologies like thermal-magnetic and hybrid operation, ensuring precise protection and minimizing downtime․ Regular inspection and maintenance of commercial circuit breakers are essential to guarantee continuous operation and safety in dynamic business environments․

Advantages and Disadvantages

Circuit breakers offer numerous advantages, including reliable protection against overcurrent and short circuits, ensuring safety and preventing equipment damage․ They provide easy operation, both manually and automatically, and are versatile for use in residential, industrial, and commercial settings․ Additionally, circuit breakers are reusable, eliminating the need for frequent replacements like fuses․ However, they also have some disadvantages․ High initial costs, complex installation, and periodic maintenance requirements can be drawbacks․ Certain types, like thermal-magnetic breakers, may have sensitivity issues, tripping unnecessarily under specific conditions․ Moreover, circuit breakers for high-voltage systems can be bulky and require specialized handling․ Despite these limitations, their benefits in ensuring electrical safety and system reliability make them indispensable in modern electrical systems․

Safety Considerations

Ensuring safety when working with circuit breakers is paramount to prevent electrical hazards․ Always de-energize the circuit before performing maintenance or repairs to avoid electrical shocks․ Personal protective equipment, such as insulated gloves and safety glasses, should be worn to protect against arc flashes or electrical discharges․ Proper training is essential for handling circuit breakers, especially high-voltage types, to understand their operation and potential risks․ Regular inspections and testing of circuit breakers are crucial to ensure they function correctly during faults․ Additionally, adherence to local electrical codes and manufacturer guidelines is necessary to maintain a safe working environment․ Ignoring safety protocols can lead to severe injuries or fatalities, making it critical to prioritize caution when interacting with electrical systems․

Maintenance and Testing

Regular maintenance and testing of circuit breakers are crucial for reliable operation and longevity․ Visual inspections help identify wear or damage, while mechanical and electrical tests ensure proper functionality․ Cleaning contacts and tightening connections prevent arcing and resistance issues․ Advanced diagnostics, like thermal imaging, detect potential faults early․ Following manufacturer schedules ensures safety and performance․ Keeping maintenance records aids in tracking and planning, complying with standards and extending breaker lifespan․

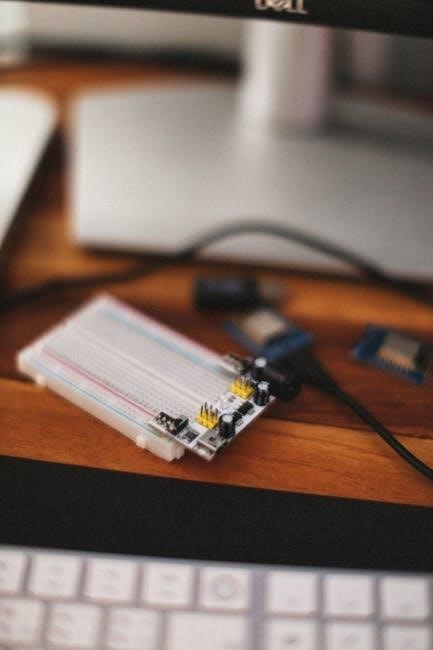

Future Trends

Future trends in circuit breakers focus on advancing technology and sustainability․ Smart circuit breakers with IoT integration will enable real-time monitoring and remote control, enhancing reliability․ DC circuit breakers are gaining traction for renewable energy and electric vehicles․ High-voltage DC systems are being developed for grid-scale applications․ Solid-state circuit breakers using semiconductors will offer faster switching and higher efficiency․ Green technologies, like eco-friendly insulating mediums, aim to reduce environmental impact․ Predictive maintenance using AI and machine learning will optimize performance and lifespan․ These innovations ensure circuit breakers meet evolving electrical demands, supporting smarter and cleaner energy systems globally․

Comparison of AC and DC Circuit Breakers

AC and DC circuit breakers differ in their operational principles and applications․ AC circuit breakers interrupt sinusoidal currents, leveraging zero-crossing points for arc extinction, making them suitable for most electrical systems․ DC circuit breakers, however, handle unidirectional currents, requiring more advanced arc-quenching methods due to the absence of natural zero-crossings․ AC breakers are widely used in residential, commercial, and industrial settings, while DC breakers are gaining prominence in renewable energy systems, electric vehicles, and HVDC transmission․ DC breakers must handle higher voltages and faster fault currents, driving innovations like solid-state technologies․ Both types are essential but serve distinct roles in modern electrical systems, with DC breakers becoming critical for emerging applications․

Environmental Impact

Circuit breakers have varying environmental impacts, primarily due to the materials used in their construction and operation․ Older technologies, such as oil and SF6 circuit breakers, pose significant environmental risks․ SF6, while effective, has a high global warming potential, leading to its phase-out under international agreements․ Oil circuit breakers also raise concerns due to potential oil leaks and contamination․ In contrast, vacuum and air circuit breakers are more environmentally friendly, eliminating the need for hazardous substances․ The industry is shifting towards these eco-friendly alternatives to minimize ecological damage․ Additionally, proper disposal and recycling of circuit breakers are crucial to prevent harmful materials from entering landfills․ As regulations tighten, manufacturers are increasingly focused on sustainable practices, ensuring that circuit breakers not only protect electrical systems but also the planet․

Regulatory Standards

Regulatory standards play a crucial role in ensuring the safety, reliability, and environmental compliance of circuit breakers․ Organizations such as the IEEE and IEC establish guidelines for circuit breaker ratings, testing, and performance․ These standards address voltage levels, current capacities, and short-circuit withstand capabilities․ Compliance with these standards ensures that circuit breakers operate safely across various applications․ For example, standards for SF6 circuit breakers focus on minimizing emissions due to their high global warming potential․ Manufacturers must adhere to these regulations during design and testing to guarantee product safety and environmental sustainability․ Regular updates to these standards reflect advancements in technology and evolving safety requirements, ensuring circuit breakers meet the demands of modern electrical systems while protecting people and the environment․

Circuit breakers are essential components in electrical systems, providing protection against overcurrent and short circuits; With various types like air, oil, SF6, and vacuum circuit breakers, each offers unique advantages tailored to specific applications․ Advances in technology have led to more efficient and environmentally friendly designs, such as hybrid and DC circuit breakers․ Regulatory standards ensure safety and performance, while ongoing innovations promise even better solutions for future electrical demands․ Understanding the different types and their roles is crucial for selecting the right breaker for any system, ensuring reliability, safety, and compliance with global standards․ As electrical systems evolve, so too will circuit breakers, adapting to new challenges while maintaining their critical protective function․